Automotive

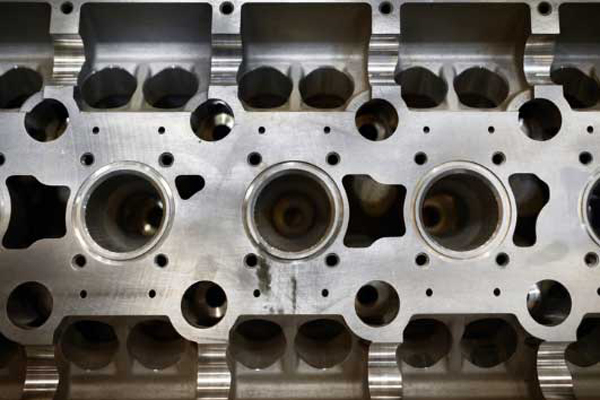

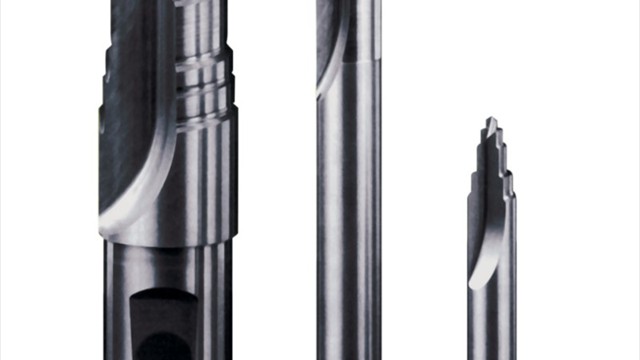

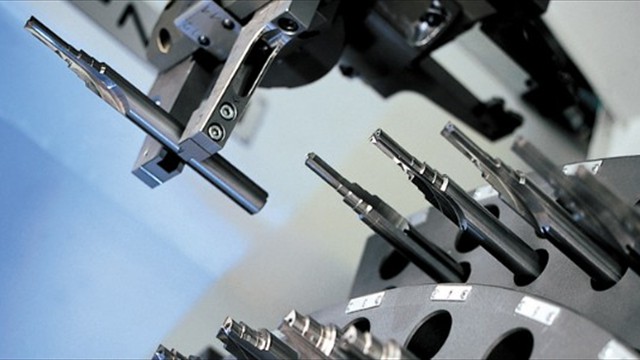

Many of our customers are active in the automotive industry. In this industry, the reduction of cycle times plays an essential role. And exactly for this application the custom made tools of Schwegler are made for: We are specialists in reducing tool changes or even avoid them completely. So with our tools many complex machining processes can be managed in one single operation.

Minimalism also in terms of cooling liquid: We at Schwegler master the minimum quantity lubrication which has become so important in the automotive sector (German: Minimalmengenschmierung/MMS). By the massive reduction of the coolant liquid several advantages for our customers are acquired. Most important: for the same achievement less energy is necessary. Moreover the cost for the coolant liquid itself is minimized.

Automotive

Die MMS-advantages in overview:

Financial advantages

• Huge cost savings through omission of all infrastructure concerning cooling liquid

• Optimized processes lead to longer life cycles and a shortened process cycle

• Cost for purchasing, storing and transport of cooling liquid are reduced significantly

• No Maintenance of a cooling system necessary

• Cleaning process of the machined parts is minimized

• Dry metal chips can be sold as recycling material (wet chips have to be cleaned first)

Ecological advantages

• No more emulsions that have to be disposed

Health and employment Safety

• The dry machine location minimizes the risk of work accidents

• Human intolerances of cooling liquids are avoided

1

1 2

2 3

3 4

4 5

5 6

6 7

7