Schwegler-Workflow

Where every wish is fulfilled

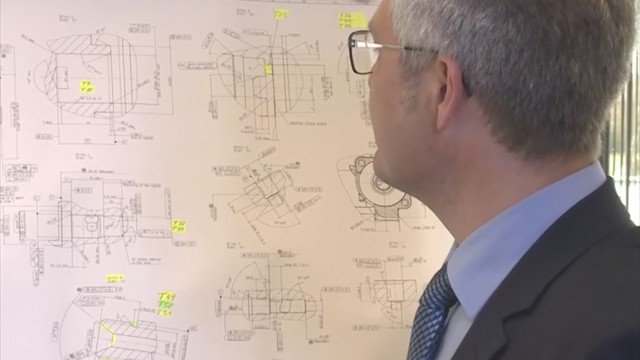

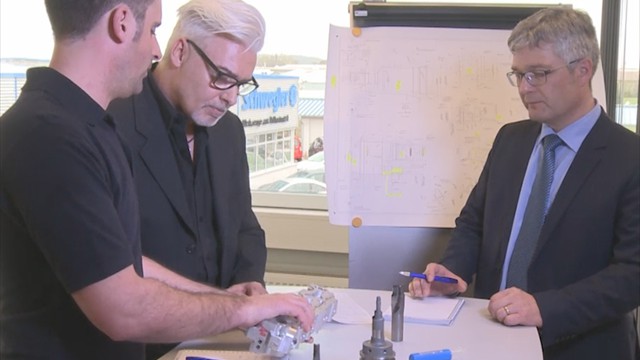

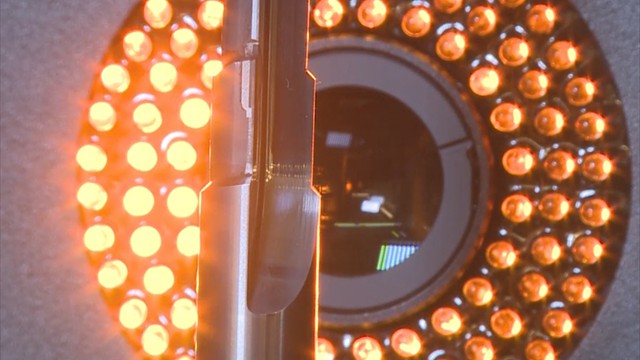

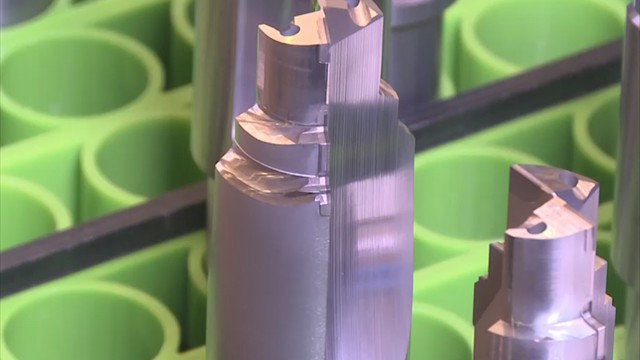

The Schwegler-Workflow has proved itself reliable in the most diverse challenges and in various industries. The first step and the basis for every project is the intensive analysis and in-depth-discussion where all relevant production parameters as coolant pressure or feed rate etc. are considered. Which cutting material, which geometry, which coating – together with the customer we decide on the ideal process and tool design, which is later on manufactured in our high-end production. Pre-machining, external-cylindrical grinding, forming operation, measuring technique, surface preparation and extensive quality controls are all part of the professional Schwegler manufacturing.

Numerous services, for example laser inscription and a clever logistic solution perfect the workflow that leaves no wish unfulfilled.